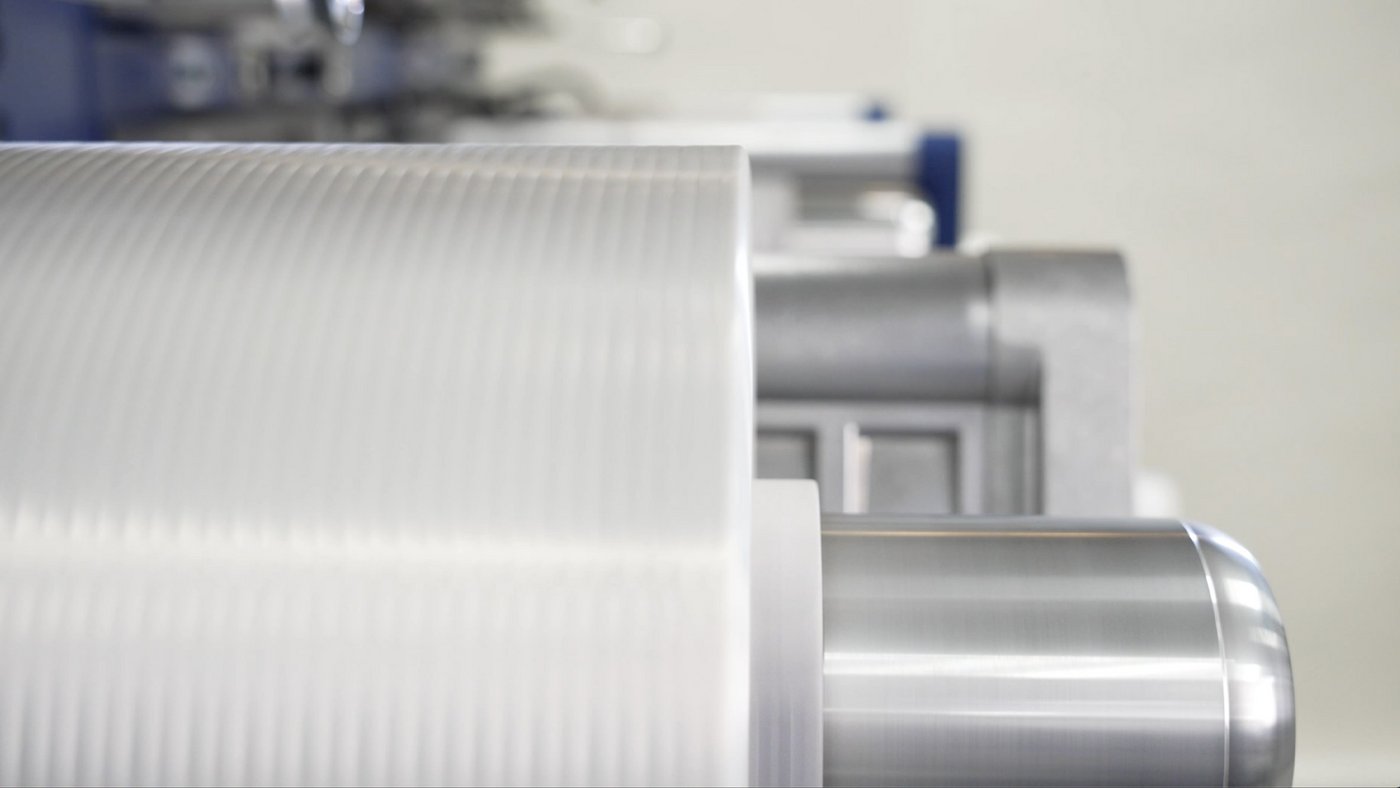

TWINSTAR II - The trusted industry leader

Flexible for multiple applications

TWINSTAR II is the flexible solution for all your winding needs. The state-of-the-art system lets you handle a wide range of winding materials and provides perfect winding performance for a broad array of yarn counts, package sizes and shapes.

The TWINSTAR II technology is designed to work seamlessly with cylindrical tubes made of many different materials, including paper, aluminium and steel.

APPLICATIONS

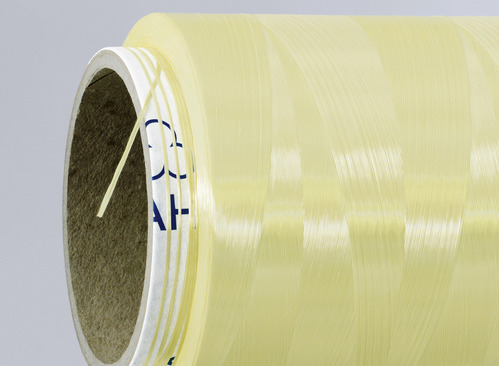

- High performance fibers

- Multifilaments

- Tapes and monofilaments

- Coated and twisted yarns

- Hollow fibers

- Hybrid materials

Others on request

Top performance in diverse use scenarios

Top performance for multiple parameters

| Winding speed | Up to 3,000 m/min |

| Yarn count range | 30 to 20,000 dtex* |

| Traverse lengths | 190.5, 200, 250, 260, 300, 305 mm* |

| Option: Changeable mechanical double traverse lengths | 190.5 and 260 mm / 190.5 and 250 mm* |

| Tube inside diameter | 50, 69, 73, 75, 76.2, 82.55, 90, 94 mm* |

| Package diameter | Max. 320 mm* |

| Package weight | Max. 20 kg* |

| Yarn tension | 30 to 1,200 cN* |

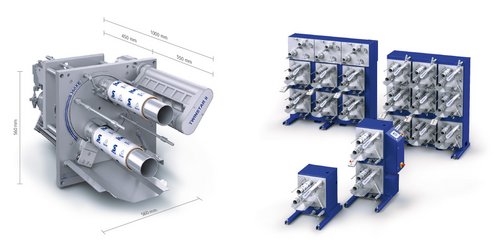

| Frame | 1-tier, 2-tier, 3-tier - single frames and group frames; winding units without frame for implementation in customer's frame design |

Combination of all maximum values is not possible. * Others on request

Standard Features

| Options

|

| Please see also "Design your own TWINSTAR II" below. |

Compact and modular design - Peak performance with minimum space

Your advantages

Design your own TWINSTAR II

For peak winding performance customized exactly to your needs

Bobbin push-off device with parking position

Bobbin push-off device with parking position

During automatic bobbin changeover, the finished bobbin is pushed into a parking position while the next bobbin is already being wound. Perfect for automated doffing and higher flexibility for manual doffing.

Yarn reserve

Yarn reserve

Adjustable yarn reserve with minimum yarn tail after automatic changeover.

NEW: Flexible Traverse

NEW: Flexible Traverse

You get full adjustability for: traverse width, bobbin shape, bobbin positioning and yarn reserve choice.

Pull roll (godet)

Pull roll (godet)

Godet per winding head pulling the yarn from the preprocess.

Winding direction

TWINSTAR II series provides a winding head assembly for q-wind direction as a standard while a mirror-inverted assembly for p-wind direction is available as an option.

Intermingling

Intermingling

Air entanglement of single or assembled multifilament yarns while the yarn length of several assembled ends is kept equal (low catenary effect) and the cumulative strength of the yarn is maintained.

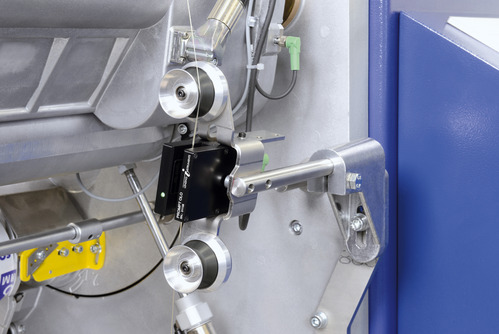

Quality sensor

Quality sensor

Monitoring of yarn thickness to check for broken filaments and problems with material quality.

Customized yarn guide assemblies

With/without knot deflector and/or melt catcher.

Diameter monitoring/control

Online yarn diameter monitoring, with optional closed- loop system for control of the diameter regulated by the winding speed. Separation of the production whenever material leaves the tolerance range.

Double cam

Double scroll cam for two different traverse lengths.

Yarn cutter

Automatically controlled pneumatic cutting device per winding position provides a clear shear cut of yarns during start-up and refeeding processes.

Yarn suction device

Automatic yarn suction device per winding position for higher operator convenience during start-up and refeeding processes.

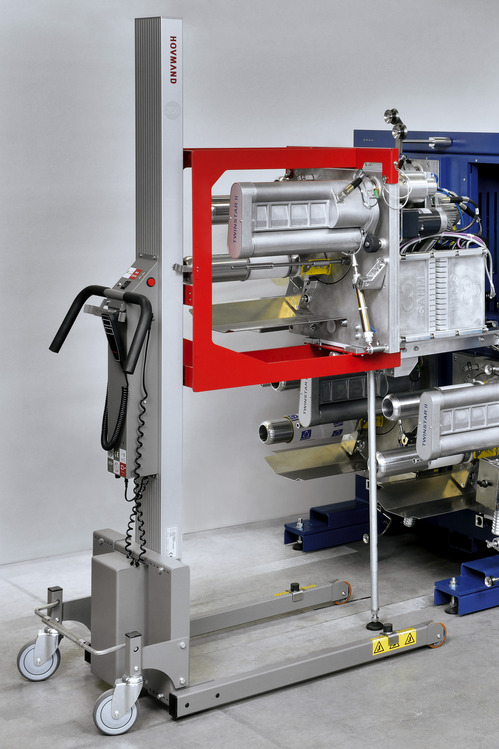

Winding head change connector

Easy maintenance unit with and without easy change connector (ECC), helps to quickly disconnect and remove the winding head for maintenance purposes.

Lifting loader

Lifting loader

Exclusive SAHM maintenance feature for secure, quick removal of the complete winding head.

NEW: Smart View

NEW: Smart View

Monitoring application to track the production of each winder.

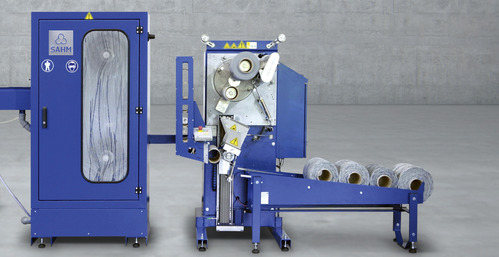

Chill Unit | Easy Storage Doffer (ESD)

Chill Unit | Easy Storage Doffer (ESD)

Yarn cooling and relaxing chamber helps avoid residual shrinkage and preserve material properties.

Easy Storage Doffer enables automatic bobbin and tube changes and intermediate storage of finished bobbins.

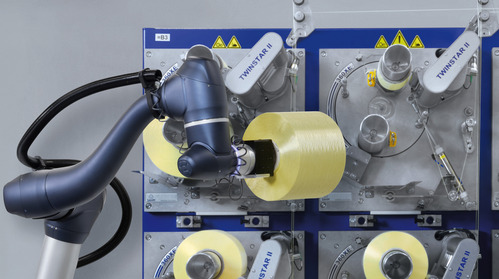

Automation

The TWINSTAR II can be adapted to different handling systems. From Easy Storage Doffers for individual winding stations to fully automated robotic solutions for large and complex production lines.

HMI

Central process control unit (HMI touch screen) for input, display and storage of process and machine parameters.

Interface

Interface to DCS (Distributed Control System) or OPC UA data exchange system.

Remote support

Remote access and support for diagnosis and guidance during troubleshooting.

Ready for automation

Ready for automation

SAHM offers scalable automation solutions for TWINSTAR II winder lines ranging from an Easy Storage Doffer for single winding positions to AGV fleet integration with robotic options and temporary bobbin storage for lines with several winding positions.

SAHM provides comprehensive winder and automation solutions for one-stop support. You have the convenience of a single design, engineering and service partner.

"You provide the task - we provide the solution"

"You provide the task - we provide the solution"

Whether a single head in a spinning mill or a complete production line with hundreds of winding heads – the TWINSTAR II fits almost everywhere.

In addition to the listed standard parameters and options for the SAHM TWINSTAR II family, manyother customer-specific features are available.

Please contact us with your requirements so that we can offer you the most suitable TWINSTAR II model to fit your individual needs.

Hotline +49 5651 804-0

info@sahmwinder.com