Applications

- Security tapes and holograms

For banknotes, admission tickets, credit cards, etc.

- Aluminium/PET compound foils

For data cables automotove cables, etc.

- PP adhesive tapes (tear tapes)

For food packaging, corrugated cardboard packaging, etc.

- Various applications

Nonwoven materials for diapers, rubber bands for tires, copper tapes for solar panels, teflon tapes for sealing, prepreg tapes for textiles, etc.

The optimal roller configuration, yarn guidance technology and surface coating utility can be selected in accordance with the winding material properties.

This guarantees that all types of winding material will be handled smoothly and precisely and correctly wound onto the bobbin.

Your advantages

Technical data

| Package diameter | 400 mm | 500 mm | 615 mm | |

|---|---|---|---|---|

| Winding technology | Precision parallel winding | ✓ | ✓ | ✓ |

| Drive | Frequency controlled | ✓ | ✓ | ✓ |

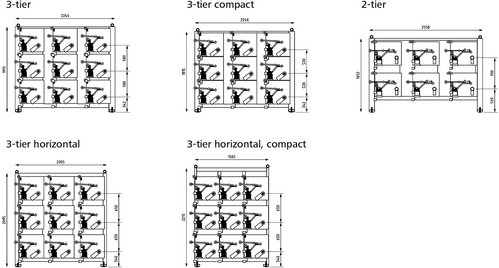

| Frame | 3-tier | ✓ | ✓ | |

| Frame | 2-tier | ✓ | ||

| Material width | 1 to 25 mm; depending on the material up to 35 mm | ✓ | ✓ | |

| Material width | Depending on the material up to 50 mm | ✓ | ||

| Winding speed | Max. 300 m/min* | ✓ | ✓ | ✓ |

| Traverse length | Adjustable up to 310 mm; optionally up to 410 or 510 mm | ✓ | ✓ | ✓ |

| Tube inside diameter | 22, 76.2 or 152.4 mm* | ✓ | ✓ | ✓ |

| Yarn tension | Electronically adjustable | ✓ | ✓ | ✓ |

| Bobbin types | Cylindrical, cops, diabolo, pancake, step winding, delta stepwinding, multiple, flange tubes | ✓ | ✓ | ✓ |

Combination of all maximum values is not possible. * Others on request

Features and Options

FEATURE

OPTION

OPTION

OPTION

OPTION

| Features | Options |

|

|

Frame Units (examples)

Integrated solutions in slitting and winding

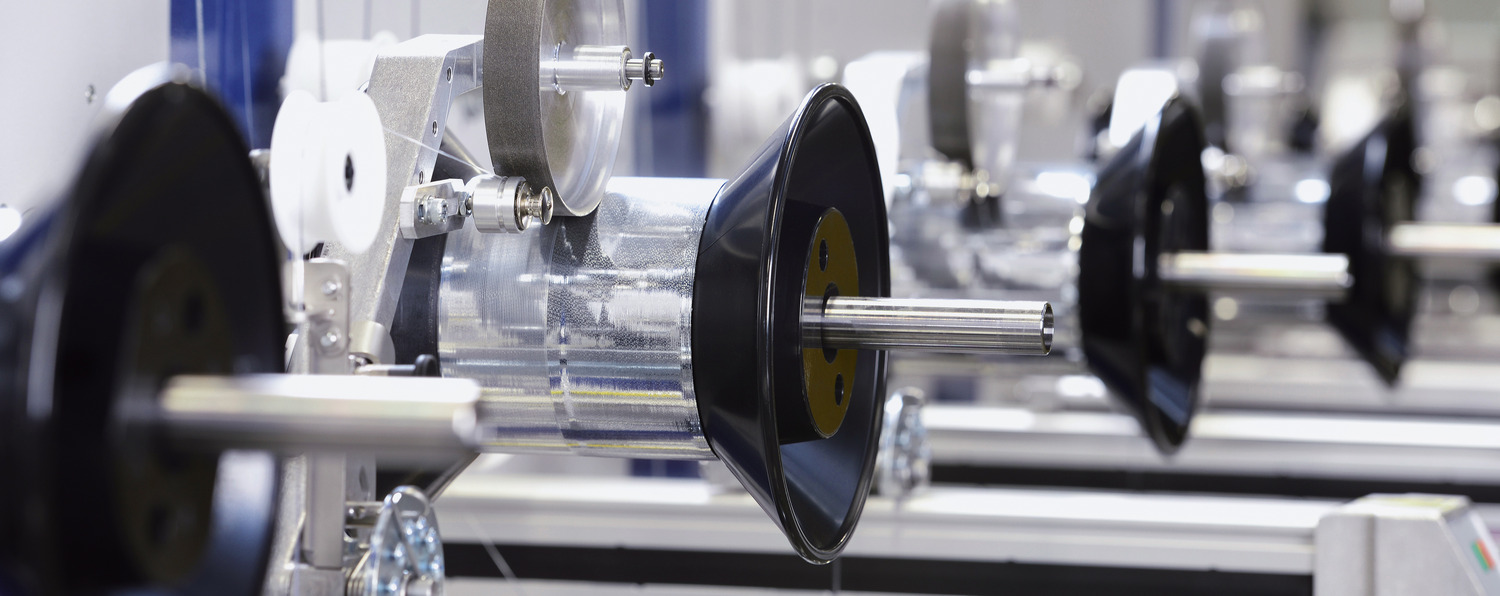

SAHM winding machines are known around the world for their outstanding precision, trend-setting technology and durable, low-maintenance designs. These are the characteristics that also make them the perfect choice for use in the converting industry.

In cooperation with well-known partners, we provide our customers with comprehensive, integrated solutions in the field of slitting and winding technology. As project leader, SAHM can take responsibility for the complete coordination and communication between the involved companies. For our customers, this means: a single contact partner for the reliable delivery of complete technology solutions.

SAHM 411XE winders with an SSM 400 slitting machine from Adolf Müller GmbH & Co. KG