SAHM 830XE & 840XE

SAHM 830XE & 840XE

Jumbo Winders for PAN Precursor Yarns

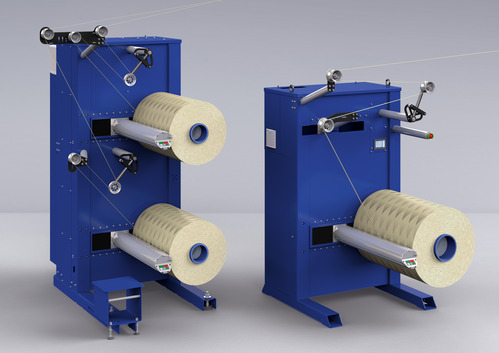

The Jumbo Winders offer modular design for heavy-weight PAN bobbins.

APPLICATIONS

- PAN precursor yarns

ADVANTAGES

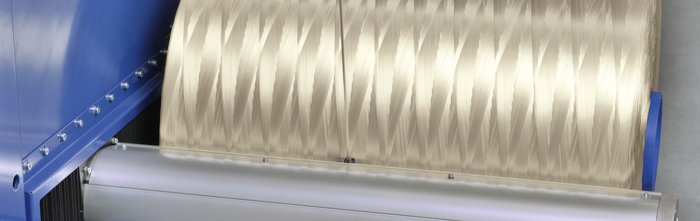

- Excellent package quality

- Modular design for heavy-weight PAN bobbins

- Alarm management (yarn break, yarn length, package diameter)

- Electronic input of all winding parmeters

FEATURES

- Electronically controlled variable winding ratio

- Central process control unit (HMI touch screen) for input, display and storage of process and machine parameters

- Speed synchronization with the preceeding process

- Pneumatic mandrel

- Doffing timer function

- Easy doffing spindle (option for 830XE and standard for 840XE)

OPTIONS

- Easy doffing spindle (option for 830XE and standard for 840XE)

- Suction device for doffing procedure

- NFC tag technology

Highlights

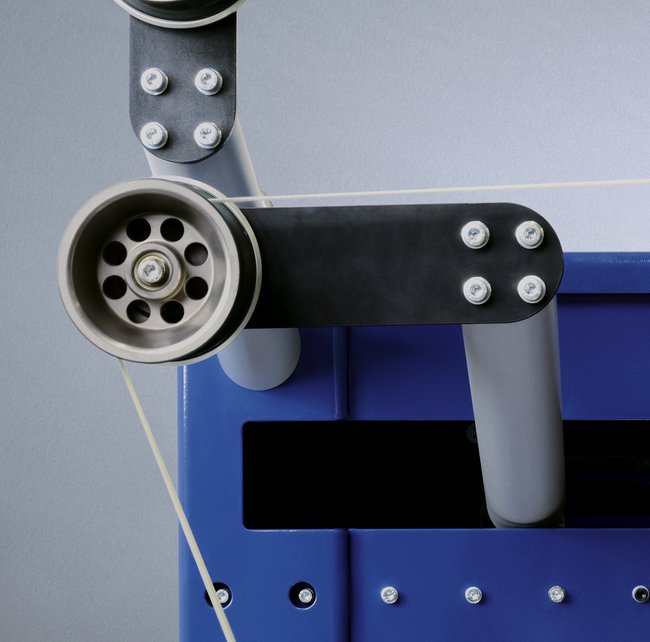

Innovative yarn entrance

Patented yarn entrance maintains a constanct angle as package diameter increases to improve the quality of fiber by reducing friction on the yarn guide.

Pneumatic doffer

The pneumatic doffer supports wireless comminication with the handling system.

Easy doffing spindle

The ball bearing spindle design with homing sensor technology reduces spindle wear and faciliates bobbin doffing.

Ready for Industry 4.0

NFC tag technology Remote Support capability Prewarning and alarm system via WiFi and/or SIM network OPC data transfer technology Communication with DCS and robot handling systems

Technical Data

| SAHM 830XE | SAHM 840XE | |

|---|---|---|

| Winding technology | Precision cross winding | Precision cross winding |

| Drive | Frequency-controlled | Frequency-controlled |

| Frame | 1- or 2-tier | 1- or 2-tier |

| Titer | 3 to 60 K (others on request) | 12 to 60 K (others on request) |

| Winding speed |

50 to 150 m/min for wet spinning, 200 to 550 m/min for air-gap spinning (others on request) |

50 to 150 m/min for wet spinning, 150 to 450 m/min for air-gap spinning (others on request) |

| Traverse length | 700 mm | 800 mm (others on request) |

| Package diameter | Max. 800 mm | Max. 1,000 mm |

| Tube inside diameter | 133, 140 and 144 mm (others on request) | 190 mm (others on request) |

| Tube length | Max. 750 mm | Max. 850 mm |

| Package weight | Max. 300 kg | Max. 500 kg |

Combination of all maximum values is not possible.

Examples

Frame Units